Key Notes for Escalator Comb Plate Maintenance

Key Notes for Escalator Comb Plate Maintenance. While purchasing comb, what is information you need to prepare?

Jul 13,2025

By following these, we safeguard passenger safety and ensure the escalator runs smoothly. https://www.deysse.com/product/Escalator-Spare-Part-Aluminum-Comb-Plate-Left-3389.html

For quality comb plates, visit www.deysse.com

1. Escalator Model and Specifications

- Brand and Model of the Escalator

Provide the exact brands and model number of the escalator. Different models may have customized comb plate designs in terms of size, tooth shape, and installation dimensions. - Technical Parameters

Include parameters like the step pitch (the distance between adjacent steps, usually a standard value such as 100mm or 120mm, but specific to the escalator), and the width of the escalator (e.g., 800mm, 1000mm wide escalators use different comb plate sizes).

2. Comb Plate Details

- Existing Comb Plate Dimensions

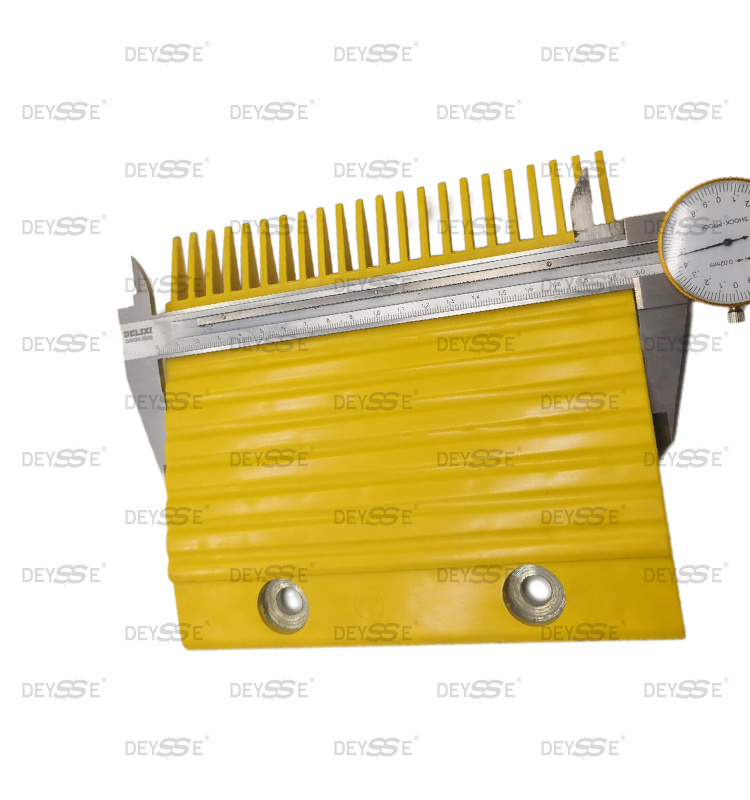

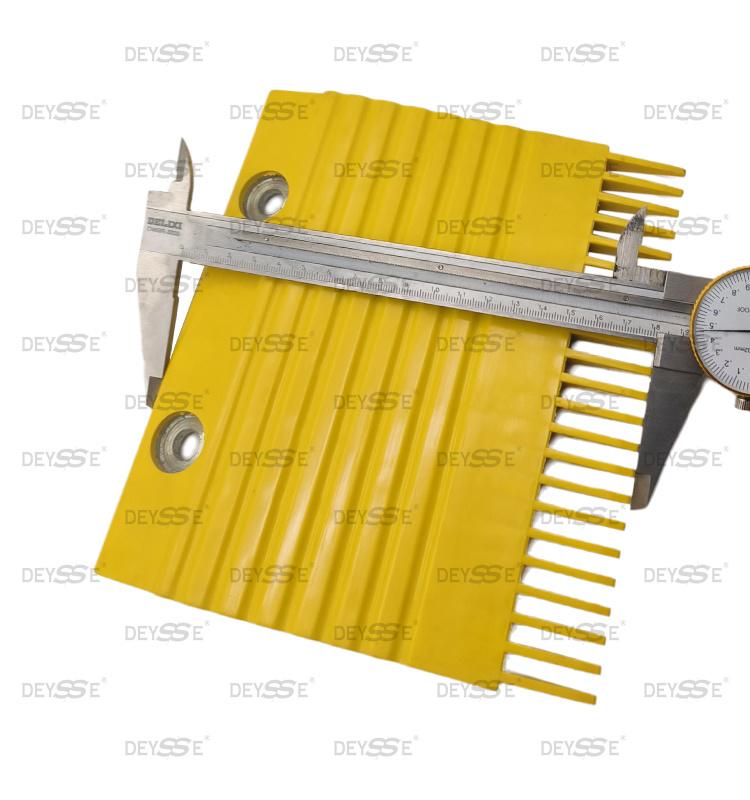

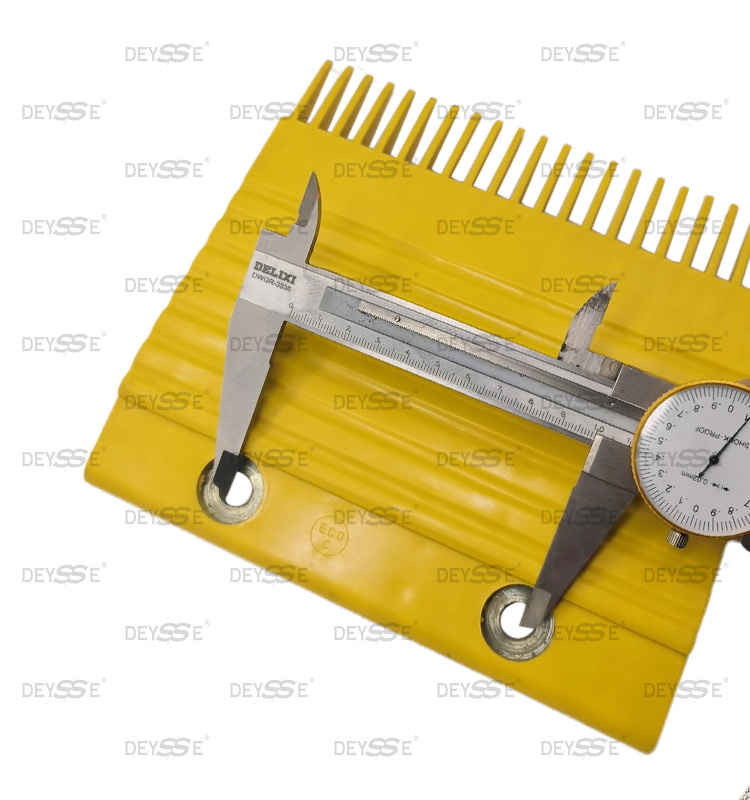

Measure and supply the length, width, and thickness of the current comb plate. Also, note the number of teeth and the shape of the teeth (e.g., straight - edged teeth or with specific curvatures). For instance, “Comb plate length: 300mm, width: 150mm, thickness: 10mm, 22 teeth with curved edges ”. - Material Requirements

Specify if there are special material needs, such as high - strength plastic (common for yellow comb plates visible in the picture) with flame - retardant properties, or aluminum alloy (for metal - colored ones) with anti - corrosion treatment. Like “Require comb plates made of flame - retardant ABS plastic for the yellow parts; aluminum alloy with anodized coating for the silver parts ”.

3. Installation and Compatibility Information

- Mounting Hole Positions and Sizes

Record the position (distance from the edges) an - d diameter of the mounting holes on the comb plate. This ensures the new comb plate can be properly fastened to the escalator structure. E.g., “Two mounting holes, 50mm from the left and right edges respectively, hole diameter 8mm ”.

- Compatibility with Other Components

Mention if the comb plate needs to be compatible with specific step types (e.g., full - aluminum steps, composite material steps) or skirt board designs (the side panels of the escalator) to avoid mismatches that could cause safety risks.

4. Certification and Standards

- Compliance Documents

Request that the supplier provides certificates showing compliance with relevant safety standards. - Quality Assurance

Ask for details on the quality inspection process, warranty period (e.g., “1 - year warranty against manufacturing defects ”), and after - sales support in case of installation or performance issues.

For more information, please contact with us : info@deysse.com

PREVIOUS:

Contact Person: Sean Lee

Fax: +86-20-8304-1967

Whatsapp: +8613924192218

Address: Room 2801-1,Jinhui Building,No.123 Jiefang South Road,Yuexiu District, Guangzhou, 510120 China

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Copyright ©2025 Guangzhou Deysse Elevator Fittings Co., Ltd All Rights Reserved. |

| Powered by www.300.cn | Urban substation | SEO |